Overview

In general, NOVAPLAK® can be installed using similar traditional methods used for wood or other construction materials, mainly by applying certain types of glue or PVC adhesives depending on the back structure, structure material and other site factors. For dry fix, any applicable mechanical fix including screws is applicable, depending on the use-case.

- Wet Fix

- Dry Fix

- Hybrid (A combination of Wet & Dry fix)

The relatively light weight of the panels allows for different mechanical fixes depending on the design, back structure, and application. It can be thermoformed, grind, cut, and machined on-site for final site adjustments and finishes.

WET FIX

The wet installation method, also known as a direct adhered method, is the most common method used for the installation of NOVAPLAK®. Depending on the site conditions, design, structure details, and application, this method can be coupled with additional techniques (such as adding screws or other mechanical fixes) to ensure proper, better and safer results.

- To other composite material

- To leveled concrete directly

- To metallic surfaces

- To wood

- To other construction material

Several types of glues and adhesives can be considered depending on the back structure and material, climate conditions, and application-specific needs.

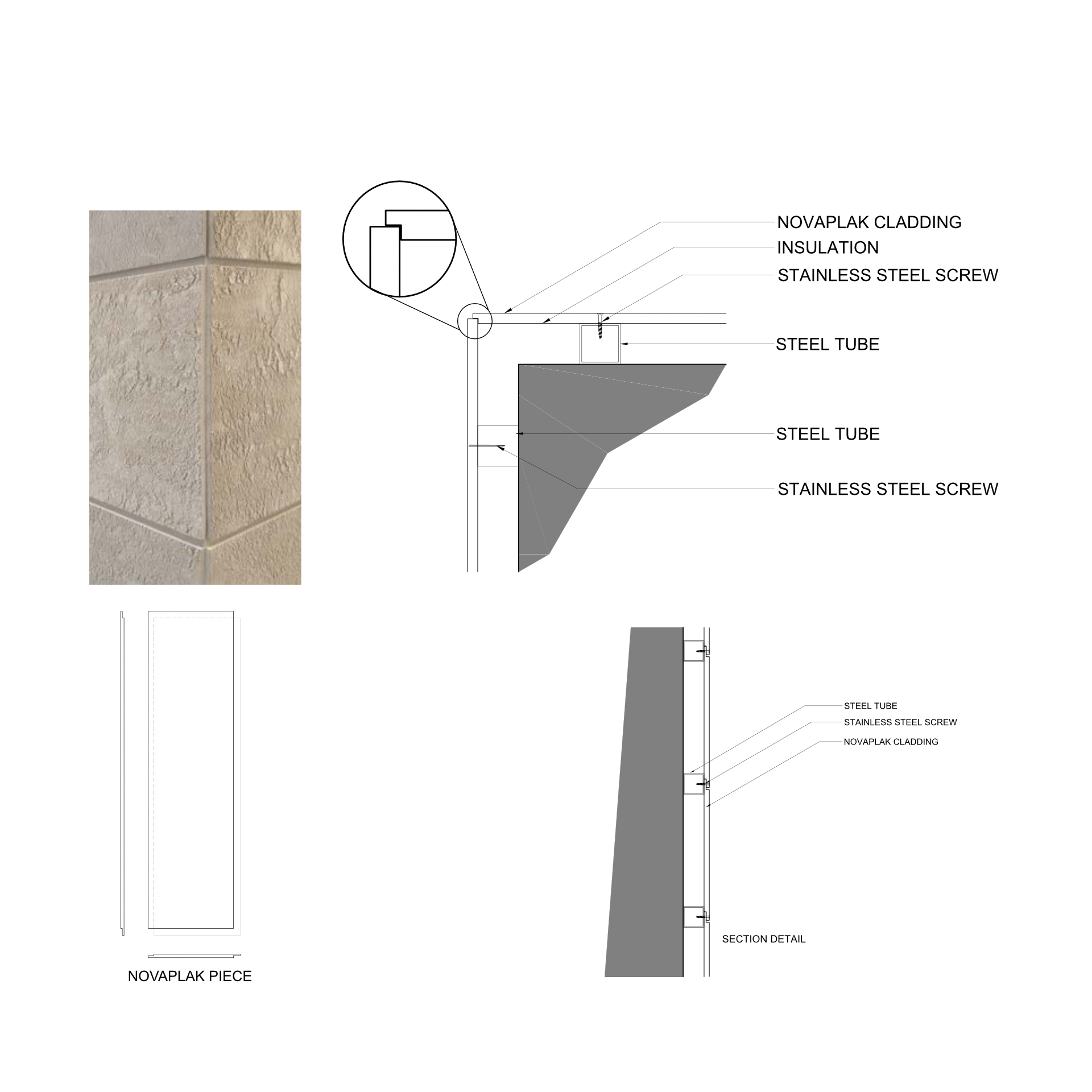

DRY FIX

The dry installation method, also known as the “mechanical installation” method uses embedded metal anchors and ties for connection purposes. The panel’s thickness required for this method must be thick enough to secure the anchors in place.

- Base & elevation cladding

- Cladding thermal bridge elimination

- Flooring

- Roofing

The dry cladding method is safe and it prevents the panels from falling off for years, hence it is recommended for exterior wall cladding applications mainly. This method allows for better expansion and contraction of the panels in extreme weather conditions making.

HIGH PRESSURED WATER

NOVAPLAK® panels do not require regular maintenance and cleaning, however, whenever required, they are are easy to service.

- Guaranteed clean surfaces

- Removes extreme stains without effort

- Dry out quickly for continued operation and use

- Easy and fast to perform in difficult locations

Any standard high-pressure water cleaner with or without a cleaning solution can be used.

JOINTS

Whenever joints are required, there are several possibilities with NOVAPLAK®.

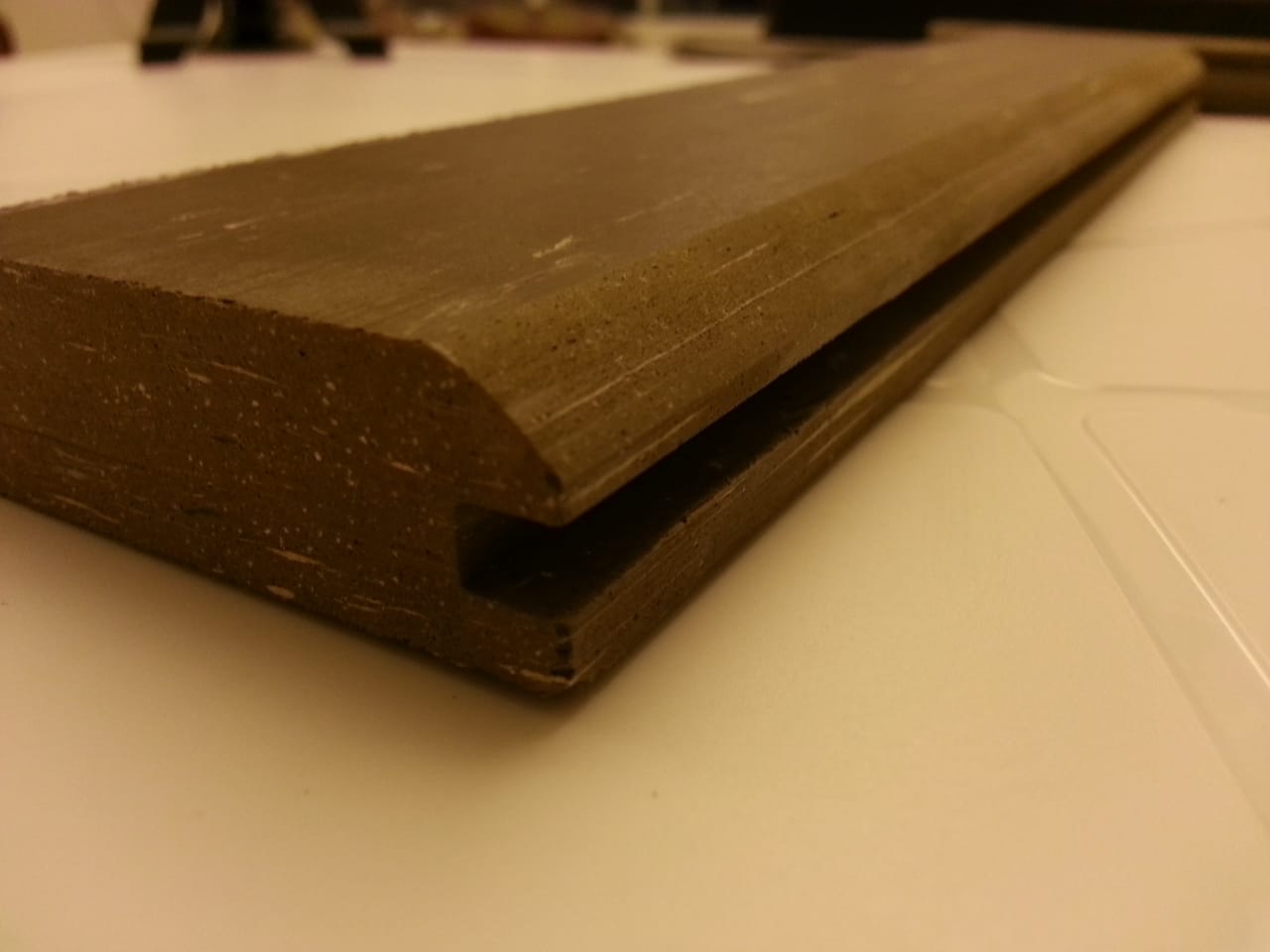

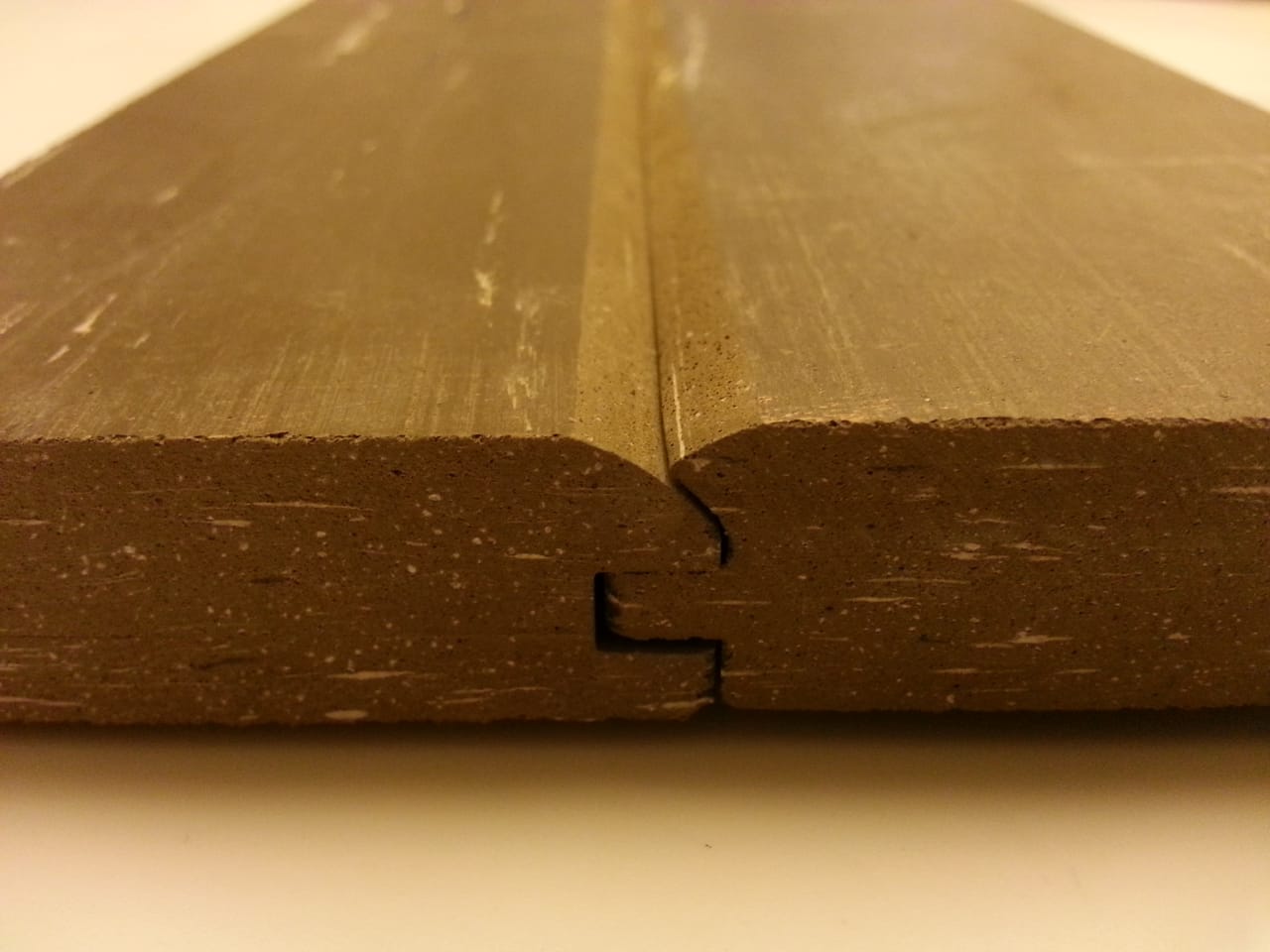

- Tongue & Groove

- Lap joint

- V Groove

- Corner

Tongue and groove can be applied to decking for flooring applications for example, whereas lap joints are usually considered for cladding and roofing. It is also possible to consider lap joints for flooring, in general, depending on underlay, site conditions, and type of application. For corners, if a thermoformed bend is not an option, standard corner joints can be considered.

Key Benefits

-

Various Fixes

01With various fix methods, NOVAPLAK® provides flexibility for fabrication and installation that suites different designs, project requirements and site conditions

-

Simplicity

02Using standard fix methods with the ability to exploit features such as thermoform-ability, light weightiness and easy machining, makes installation and fabrication simple, quick and easy

-

Flexibility

03With its many advantages, NOVAPLAK® gives you the flexibility to prepare material in the workshop or on site and always allows you the flexibility to combine both techniques to always overcome site conditions and other customisation challenges